At the beginning glance, hard-facing can be complicated and troublesome; in truth, it isn’t. Recognizing several of the basics about hard-facing can go a long way towards instilling confidence in your hard-facing item option.

The following responses to frequently asked questions may help you choose Hardfacing Start-Up Kit (wire included) items that are most ideal for your application.

What is hard-facing?

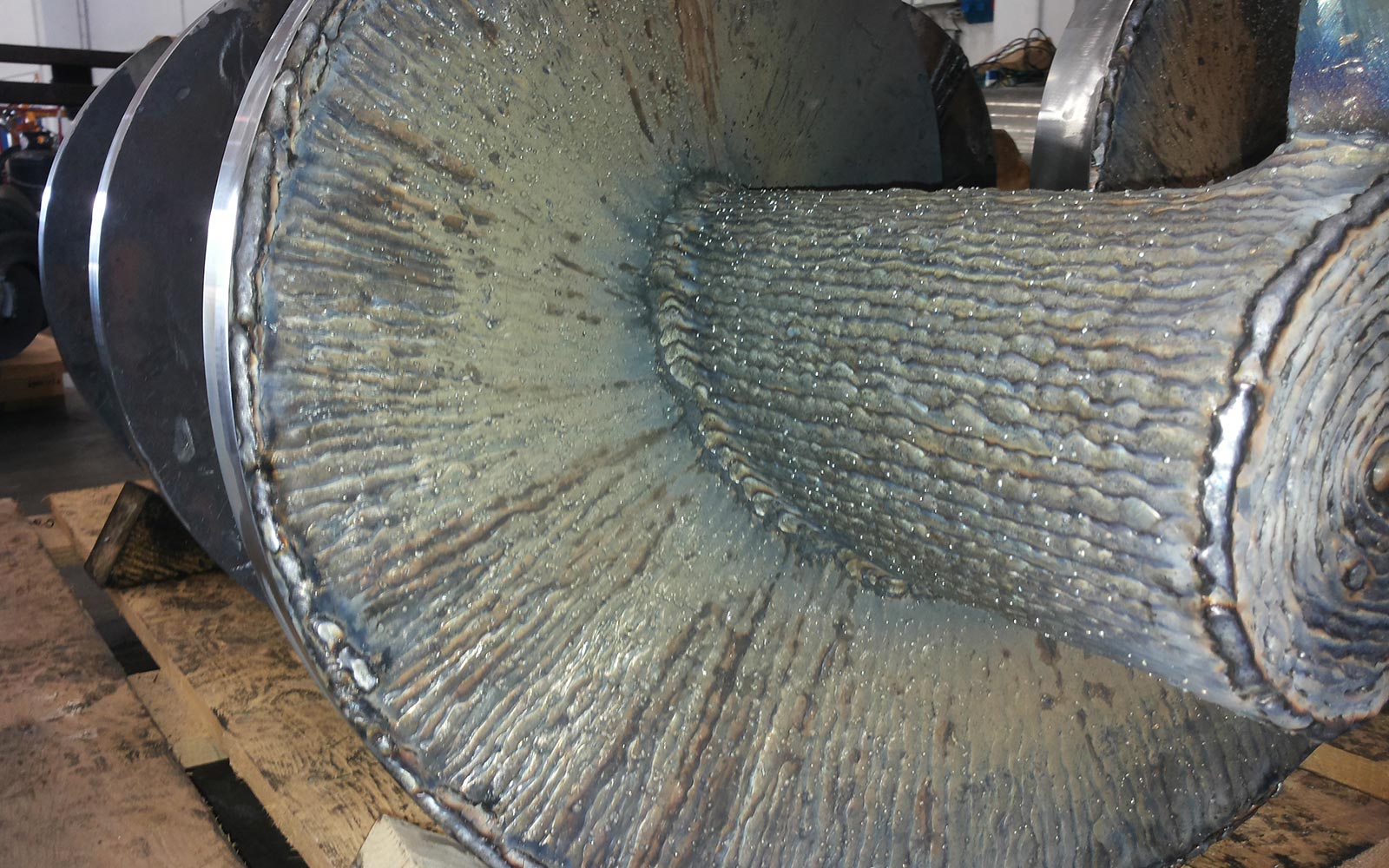

Metal components typically fail their desired usage not because they fracture, but because they are put on, which triggers them to lose functionality and measurement. Hard-facing, likewise called hard-surfacing, is the application of accumulation or wear-resistant weld steels to a component’s surface through joining or welding.

What base metals are able to be hard-faced?

Carbon, as well as low-alloy metals having carbon contents of less than 1 per cent, can be tough-faced. High-carbon alloys might require a special barrier layer.

The below base metals can be hard-faced:

- Stainless steels

- Manganese steels

- Cast irons as well as steel

- Nickel-base alloys

- Copper-base alloys

What is the most preferred treatment utilized to apply hard-facing?

In order to appeal, the adhering to procedures can be utilized:

- FCAW

- GMAW

- SMAWSAW

- GTAWOFW

- Plasma moved arc welding, thermal spray, laser welding, as well as brazing

Is there a suitable method to classify the many alloys if recognising the hard-facing for utilise?

Yes. Iron-base alloys can be divided into three major categories:

- This consists of all hard-enable steel solidity from 20-65. Firms similar to devise steel hardens upon cooling. They benefit metal-to-metal and rough wear. They additionally can endure a large amount of influence.

- Austenitic alloys consist of work-hardening metals, like manganese, as well as stainless. This team normally got soft if it is welded, as well as hardens just after the weld metal is worked. They have excellent influence properties and modest abrasion resistance. The stainless-steel household benefits from deterioration resistance.

- Steel carbide. These alloys consist of large quantities of metal carbides in a soft, tough matrix, as well as are good for severe-abrasion applications. The alloys that contain huge amounts of chromium, as well as carbon, are referred to as the chromium carbide household and are more detailed to cast iron or white iron. Their hardness is from 40-65 HRC. Alloys which contain large amounts of tungsten, as well as carbon come from the tungsten carbide family. Some have small amounts of boron and chromium that create borides and benefit severe-abrasion applications.

To buy items from Tungco, please visit the link.